Which kind of Turbine Oil Purifier machine will achieve the best results?

The oil used in the adjustment and lubrication system of the steam turbine generator set will mix steam, water or impurities to different degrees throughout the course of its operation. It requires frequent maintenance and treatment. Otherwise, it may accelerate the deterioration of oil quality, cause adjustment and protection system failures, result in bearing bush damage or otherwise influence safe operation of the unit.

In the past, medium and small units generally used a regular pressure oil purifier machine and a centrifugal oil purifier machine to remove impurities and water from the running oil. However, the operation of these two kinds of equipment is complicated and results in a high amount of oil waste. The efficiency of filtering out water and impurities is too low, and the operation requirements of the unit cannot be met.

Before, the oil purification device currently used for 200MW units mainly utilized the principle of settlement and filtration. Its basic structure consists of a sedimentation tank, a filter tank and a storage tank. A multi-layer separation net is arranged in the sedimentation tank. Depending on the gravity difference between the oil and the water, the water in the oil condenses into water droplets as it passes through the separation net, settling in the lower part of the tank before it is discharged from the outside of the tank by an automatic water pump. This oil purifying equipment has a large design capacity and size, and from a practical use perspective, experienced widespread phenomena such as poor water removal efficiency, dirty oil, and easy clogging of purification devices. In addition, there is also an ordinary vacuum type purifying machine, which uses the principle of flushing to remove water and removes impurities with a mesh filter. Such a device is suitable for removing trace water in oil, but for a unit with serious water leakage, and especially emulsified oil, it can’t sustain treatment and isn’t suitable for continuous operation.

The Turbine oil characteristics and problem are as below:

- Water and gas are in two forms in the oil – dissolved water and gas (below the saturation point) are present in most oil systems and oil equipment, and free water and gas (above the saturation point) are present in many oils.

- Due to issues such as system leakage, poor sealing, long-term thermal loads of oil, open storage, and more, moisture and gas in the air settle in the oil, resulting in water and gas in the oil.

- As the system leaks, the dust in the air enters the system and the dust falls off. The oil labors for a long time under high temperature conditions and water. It will inevitably cause some of the oil to crack and create a gelatinous substance.

What damage is caused by water, gas and impurities in the oil?

- Rapidly oxidizes and degrades the oil to form acidic substances and corrode metal contact surfaces

- The precipitation of the additive in the oil fails, the thickness of the lubricating film is reduced, and the mechanical wear is increased

- Lubrication, cooling, and reduced flow properties accelerate metal surface fatigue

- Ice crystals formed at low temperatures block components and reduce system rigidity

- System response is slow and accompanied by irregular motion conduction performance degradation

- Higher oil temperature does not cool

- Oil pump and power equipment are damaged by cavitation

Now, according to turbine oil characteristics, we’ve designed the YH-TY series turbine oil purifier machine to filter out the water, gas, impurities and volatile matters, (methanol, ethanol, acetylene, hydrogen, methane, ammonia) etc. and other dangerous components in the turbine oil. This further raises the quality of the oil, restoring the viscosity, cleanliness and performance of the turbine oil.

Additionally, it effectively ensures the normal operation of the usage of the turbine oil, substantially reduces the occurrence frequency of frictions, elevates the lubricating performance, and minimizes the risk of occurrence of potential incidents. It is most applicable to power generation plants, substations, power stations, oil fields, mines, metallurgical fields, electric power plants, transportation, manufacturing sectors, and other industries that require purification and regeneration of the turbine oil and all kinds of lubricating oils.

YELOCO Series YH-TY Turbine Oil Purifier machine advantages:

- Strong capabilities in filtering water and demulsification. It easily separates huge volume of water from the oil, and filters out small volumes of water in the oil as well. With the usage of a strengthened hydrophilic and hydrophobic technology (water separation device and filter elements), it comprehensively alters the interactive performances of the two interfaces between oil and water, and accelerates the activity of small little water molecules, combining them together to form a bigger water molecule big enough to be separated from the oil content. This ensures that the cloudy and emulsifying oil becomes transparent and clear.

- Strong performance in purifying impurities. It uses a filtering material that has a composite microporous structure that is corrosion-proof and heat-resistant. This is a durable and lasting device, with long-lasting usage, and the deeply-layered filtering elements within the large surface area are able to filter out the microscopic impurities from the oil content in deeper layers.

- It is mainly designed to purify the waste oils that have large water content and are seriously emulsified.

- The YH-TY series of the turbine oil purifier machine is especially adaptable and suitable for handling turbine oil, hydraulic oil, refrigeration oil and other lubricating oils that require huge amount of water elimination and precise filtering functions.

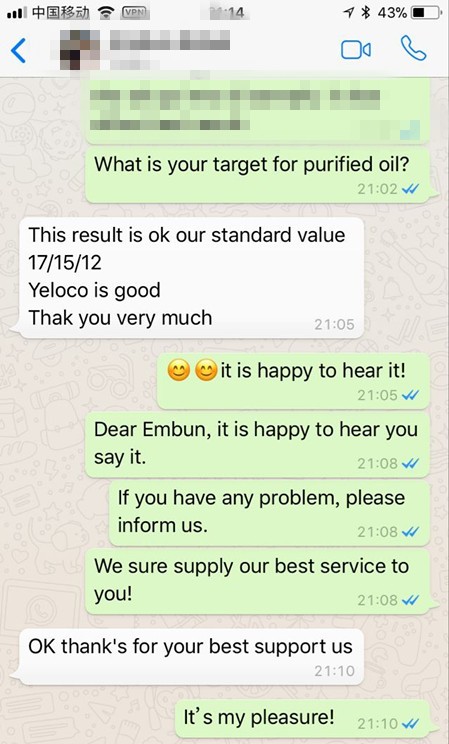

Customers are very satisfied with our YH-TY series turbine oil purifier machine quality and after services. Please see below our Turbine oil purifier machine working in customers’ place picture and customer reviews for your reference.

If you want to learn more, please contact us today.

Email: sales@yeloco.com or WhatsApp: 0086 13647641182.

FREE ACCESS

FREE ACCESS