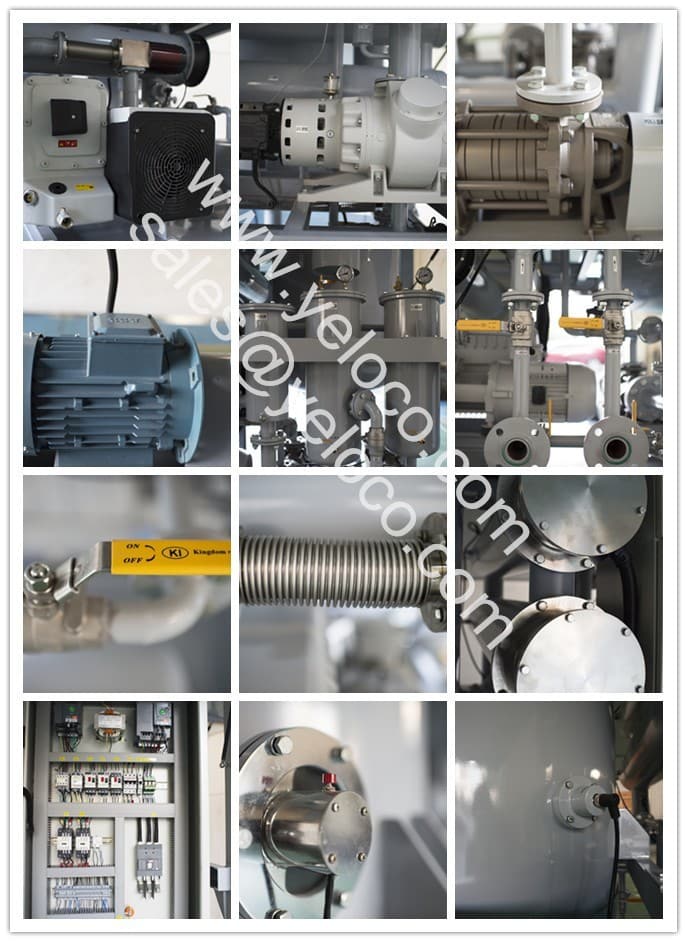

This is YELOCO series YH-ZYD-R-30(1800Liters/Hour) Double-stage vacuum Transformer Oil Regeneration and Oil Purifier machine

YELOCO series YH-ZYD-R-30(1800Liters/Hour) Double-stage vacuum Transformer oil regeneration machine can bring benefits to you as below:

- It keeps the KV of your oil above the required level.

- Removes explosive gas from the oil.

- Removes moisture and impurities from oil thoroughly.

- Removes acidity, sludge, free carbon, other soluble oil decay products and discoloration.

- It increases the life of not only the transformer but also the oil.

- Have the function of Dehydration for Transformer oil.

- It can vacuum pump for the Transformer and vacuum filling oil for the power transformer.

- The series YH-ZYD-R system not only provides regular oil purification such as degassing, drying and particulate removal but also can remove acidity, sludge, free carbon, other soluble oil decay products and discoloration. This is accomplished by the use of high vacuum degasification technology and regeneration filters combined with our special brand of earth. After treating, the oil can be reused as new.

The series YH-ZYD-R-30(1800Liters/Hour) Double-stage vacuum Transformer Oil Regeneration and Oil Purifier machine operation is very simple. Please see below:

USAGE AND OPERATION

* Place the equipment on the horizontal ground smoothly

* Connect power cables

* Fasten all wiring terminals in the electric control cabinet

* Connect the inlet and the outlet of the oil pipe, open oil inlet valve and oil outlet valve

Automatic operation of products

* Start up procedure

Turn the “Automatic/ Manual” knob switch to the “Automatic” position and press the “Start” button switch. Under the control of the programmable logic controller PLC, the equipment will orderly control various motors, heaters, AC contactor and other components.

* Shut down procedure

In the automatic operation state, press the “Stop” button directly, and the equipment will stop working orderly under the control of programmable logic controller PLC.

* Regeneration Device Operation

If you need use Regeneration device, please open Switching valve V5.5, V5.6 first, then Close Switching valve 5.8.

If you no need use Regeneration device, please open Switching valve 5.8 first, then Close Switching valve V5.5 and V5.6.

Please open the below link and watch series YH-ZYD-R-30(1800Liters/Hour) Double-stage vacuum Transformer Oil Regeneration and Oil Purifier machine operation videos for your reference.

https://yeloco.wistia.com/projects/28kylc3p3s

If you have any interesting, please contact us now email: sales@yeloco.com, website: www.yeloco.com.