- Categories

- Double-stage vacuum Transformer oil filtration machine

- Double-stage vacuum Transformer oil regeneration machine

- Single-stage vacuum Transformer oil purification machine

- Ultra-high voltage Transformer oil purifier machine for more than 350KV Transformer

- Transformer oil vacuum system

- Turbine oil purifier machine

- Lube oil filter / Hydraulic oil filter

- Online On-Load Tap Changer oil purifier

- Cooking oil purifier machine

- Waste Engine Oil Distillation machine

- High viscosity gear box oil purifier machine

- Refrigeration oil purifier machine

- Phosphate Fire-Resistant oil purifier

- Fuel oil purifier

- Portable oil purifier machine

- Oil Filling Machine

- Oil tester

Ultra-high voltage transformer oil purifier machine for more than 350KV

series YH-ZYD-U–YELOCO

Why is ultra-high voltage transformer oil purifier machine required?

Ultra-high voltage grid is known as the “power highway”, which features enhanced capacity, long distance, and low loss. There are 1,000KV, 800KV, 750KV, and 660KV available. Considering its safety, it is highly suitable for insulating oil in transformers, mutual inductors, and reactors. In order to achieve optimal dielectric strength and insulating performance inside of transformers and circuit breakers, dielectric oils must be kept absolutely clean and dry.Application:

- Used to treat new oil, running oil, particularly applicable to 220KV–1,000KV power distribution system and the national grid, shortening the oil treating duration during installation and maintenance.

- It removes acids and impurities quickly and effectively.

- It removes free and dissolved water.

- It degasses to remove other dissolved combustible gases such as acetylene, ethylene, ethane, methane, hydrogen, carbon monoxide, and carbon dioxide.

Advantages:

- The oil tank is bigger than those in common oil purifier machines.

- The oil pump uses the best quality three screw oil pump so that during the working of the oil pump, it does not make acetylene, hydrogen, and so on.

- Efficient electric heating system, heating uniformity, less power consumption, safe, and reliable. Stainless steel heating pipe surface is resistant to corrosion and has a long service life.

- Uses latent technology to dewater and degas, in order to efficiently remove the water and gas from the transformer oil. It increases the breakdown voltage over 80KV and water content less than 3 PPM.

- Adopts the double-stage vacuum system, which can highly improve the machine’s working vacuum value. It can remove the water, gas, and impurities in transformer oil efficiently, increasing and maintaining the oil's dielectric strength, making sure the electric device runs safely.

- It uses a United States special gradually close filter composite polymer material to purify the impurities effectively. It uses step-by-step encryption, proportion sharing of filter elements in addition to miscellaneous load, and reasonable fluid design to ensure the cleanliness and deep filtering of the particles from the oil. It uses electrostatic adsorption to remove negative charge carrier, reaches charge balance to completely remove impurities, and purifies the oil particle size to 1 micron.

- Double-infrared liquid level sensor; pressure protective system to ensure the machine operates easily and safely.

- Adopts an interlocked protective system, which connects oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leakage and electricity leakage. If there is any fault, the machine will turn off automatically. Operation is very safe.

- Adopts an oil-filled shockproof vacuum gauge and exact pressure gauge, and is durable.

- PTFE gasket makes it sealed, pressure bearing, and oil proof.

- The machine is equipped with online temperature inspector, voltage tester, vacuum tester, and oil level inspector. It knows the oil condition and equipment working condition at any time.

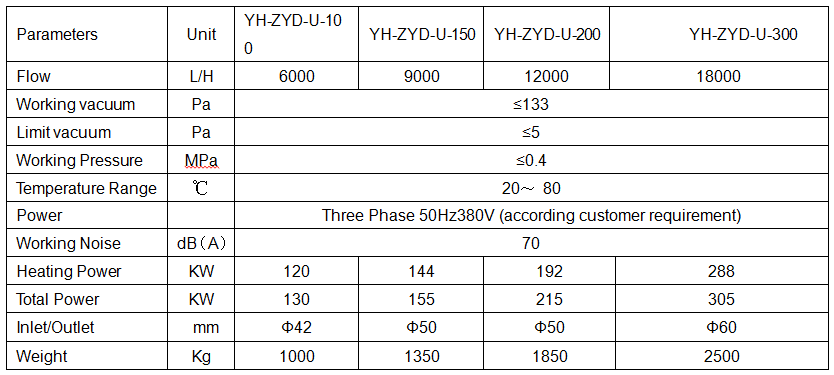

Technical Data:

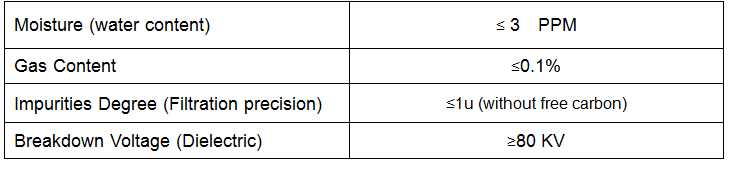

Oil Data After Treatment:

Inquiry Now

More Products

Series YH-TDT 10kV-YELOCO

DIELECTRIC LOSS TESTER/ CAPACITANCE & DISSIPATION FACTOR TEST SET/ Tan Delta tester

Series YH-COP-YELOCO

Cooking oil purifier and De-coloration machine

Series YH-TP681-YELOCO

YH-TP681 Fully-automatic interfacial tension tester

Series YH-TYR-YELOCO

Refrigeration oil purifier machine

FREE ACCESS

FREE ACCESS