- Categories

- Double-stage vacuum Transformer oil filtration machine

- Double-stage vacuum Transformer oil regeneration machine

- Single-stage vacuum Transformer oil purification machine

- Ultra-high voltage Transformer oil purifier machine for more than 350KV Transformer

- Transformer oil vacuum system

- Turbine oil purifier machine

- Lube oil filter / Hydraulic oil filter

- Online On-Load Tap Changer oil purifier

- Cooking oil purifier machine

- Waste Engine Oil Distillation machine

- High viscosity gear box oil purifier machine

- Refrigeration oil purifier machine

- Phosphate Fire-Resistant oil purifier

- Fuel oil purifier

- Portable oil purifier machine

- Oil Filling Machine

- Oil tester

High viscosity gear box oil purifier machine

Series YH-HVO-YELOCO

Application:

The High-viscosity gear box oil purifier machine is mainly used for the purification of high viscosity gear box oil and industrial lubricating oil. The machine adopts coalescence separation, dehydration, emulsification, and vacuum separation to reduce micro water content, as well as high-precision filter element to filter impurities. It is especially suitable for the purification of oil products used in lubrication systems, hydraulic systems, and more in the production line, and it can quickly and efficiently reduce the moisture content and impurity content. The treated oil meets or exceeds the use standard to meet the customer's needs.

Features:

- Coalescence separation and dehydration with strong demulsibility properties. A self-initiated photografting and photopolymerization (SIPGP) method is used to graft hydrophobic polymer polystyrene (PS) onto the surface technology of CNTs, and synergistically utilize the high roughness surface of CNTs film to obtain super A hydrophobic two-dimensional hybrid film material, which is then used to make a coalescing separation filter. The membrane is used for high throughput and efficient separation of micron and nanoscale water-in-oil emulsions. Therefore, it is easy to separate a large amount of water within the oil, and it is also convenient to remove a trace amount of water from the oil. The superhydrophobic technology is adopted to change the interaction force between the oil-water two-phase interface, so that the fine water droplets in the oil accelerate and move, coalescing into large water droplets to separate and precipitate from the oil. This process causes the turbid emulsified oil to become clear and transparent.

- Strong performance in purifying impurities. The purifying machine uses a filtering material that has a composite microporous structure. It is corrosion-proof and heat-resistant, serving as a durable and lasting device with long-lasting usage benefits. The deeply-layered filtering elements with large surface areas are able to filter out the microscopic impurities from the oil content in deeper layers.

- This device also adopts a unique water and gas separation system. The microscopic three-dimensional evaporation technology coupled with a multi-layered oil-gas separation technique rapidly separates the water content and gaseous elements from the oil fluids.

- Excellent functionality in separating water and gases. This device employs a vacuum pump with a large capacity and pumps out the vacuum from the system. On top of that, it also can eliminate the water vapour that has evaporated throughout the functionality process, alongside other gases.

- Advanced medium cooling and endothermic condensation system.

- Fully equipped with a comprehensive protection installation. The machine has a comprehensive protection module in which the original parts in this machine are subjected to strict compliance to temperature changes, pressure changes, degree of vacuum, power surges, and more. In addition, it is able to effectively prevent the occurrence of incidents and ensure normal operation continues at all times.

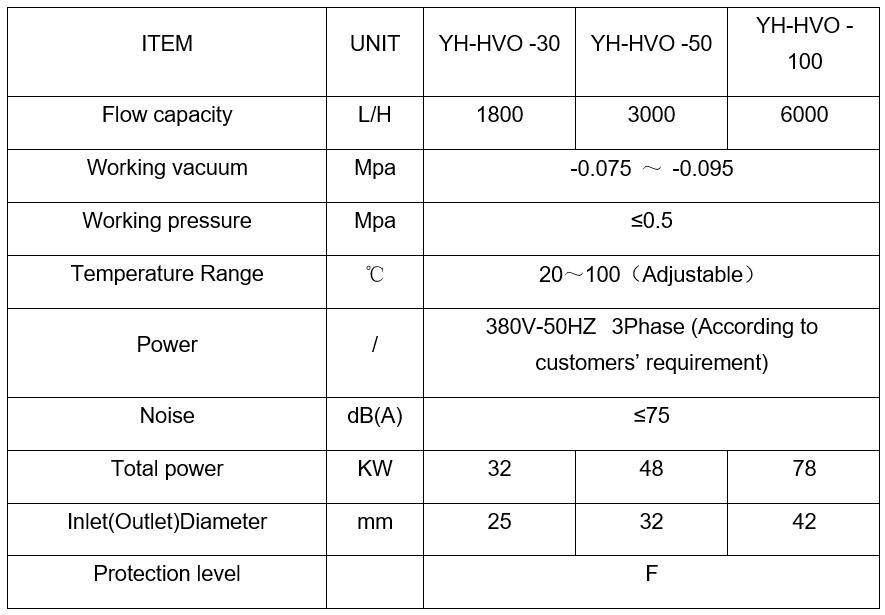

Technical Data

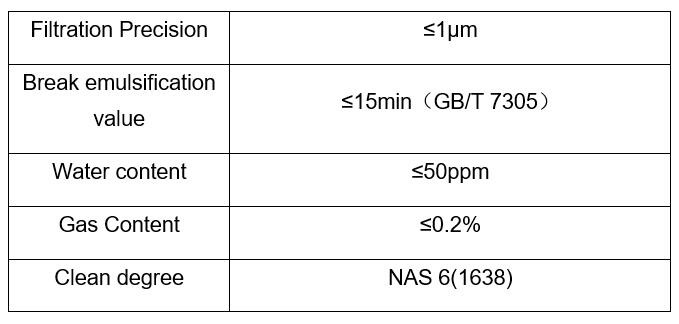

Oil Data After Purification

Inquiry Now

More Products

Series YH-TP692-YELOCO

YH-TP692 Petroleum Products Color Tester

series YH-TYB–YELOCO

Fuel oil purifier

Series YH-TP526-YELOCO

Fully-automatic Pour Point &Solidifying Point Tester

series YH-TYD–YELOCO

Oil water separator

FREE ACCESS

FREE ACCESS