- Categories

- Double-stage vacuum Transformer oil filtration machine

- Double-stage vacuum Transformer oil regeneration machine

- Single-stage vacuum Transformer oil purification machine

- Ultra-high voltage Transformer oil purifier machine for more than 350KV Transformer

- Transformer oil vacuum system

- Turbine oil purifier machine

- Lube oil filter / Hydraulic oil filter

- Online On-Load Tap Changer oil purifier

- Cooking oil purifier machine

- Waste Engine Oil Distillation machine

- High viscosity gear box oil purifier machine

- Refrigeration oil purifier machine

- Phosphate Fire-Resistant oil purifier

- Fuel oil purifier

- Portable oil purifier machine

- Oil Filling Machine

- Oil tester

Cooking oil purifier and De-coloration machine

Series YH-COP-YELOCO

Application:

The YH-COP Series Cooking Oil De-Coloration Machine impacts the physical treatment, on the premise of not affecting the components and the performance of the oil, to rapidly remove the color, moisture, impurities (particulate impurities and mechanical impurities), gases and other harmful ingredients, etc. in the cooking oil, thus improving the quality and properties of the oil. This purified oil can be used for the creation of biodiesel and so on.

It is also capable of treating fryer oil, vegetable oil, coconut oil, sunflower oil, turmeric oil and so on. The treated oil is very clear and transparent as a result of the treatment process.

Working Principle:

The equipment’s process sees the oil transported through the primary filter via the oil inlet pump to remove large particles and impurities whilst protecting the oil inlet pump. Next, the oil runs into the pre-heater for heating, in order to improve the liquidity of the oil, which is important for the next process.

After heating, the oil runs through the secondary filter by the effect of pressure to remove small particles in the oil, and then the oil enters the vacuum vessel which adopts the molecular separation technology.

With certain vacuum and temperature conditions, a large area of multi-level vacuum evaporation space is formed. This provides the oil with a retention process that includes a large aeration area and aeration time, and ensures the effective separation of oil and gases or water vapors.

The mixture of evaporated water vapor and gases is condensed into liquid through the cooler, and the gas is then pumped out via the vacuum pump. This method completes the dehydration and degassing treatment. The high temperature water vapor and other gases evaporated from the vacuum vessel are cooled twice by the condensing cooler. Most of the gas is reduced to water before it is stored in the water receiver.

After being repeatedly cooled and dehumidified, the uncondensed gas is discharged from the exhaust port of the vacuum pump. The dehydrated oil is exported out through the oil outlet pump, and runs through the fine filter to remove the fine impurities and finish the filtration process of dehydration and degassing. The pre-treated oil is then returned to the oil storage tank before it is transported to the regeneration device via the oil pump. After a period of absorption and neutralization treatment, it is sucked and stored in the tank by the vacuum vessel, transported to the fine filter through the oil pump, and discharged from the oil outlet. This process results in clean and clear oil.

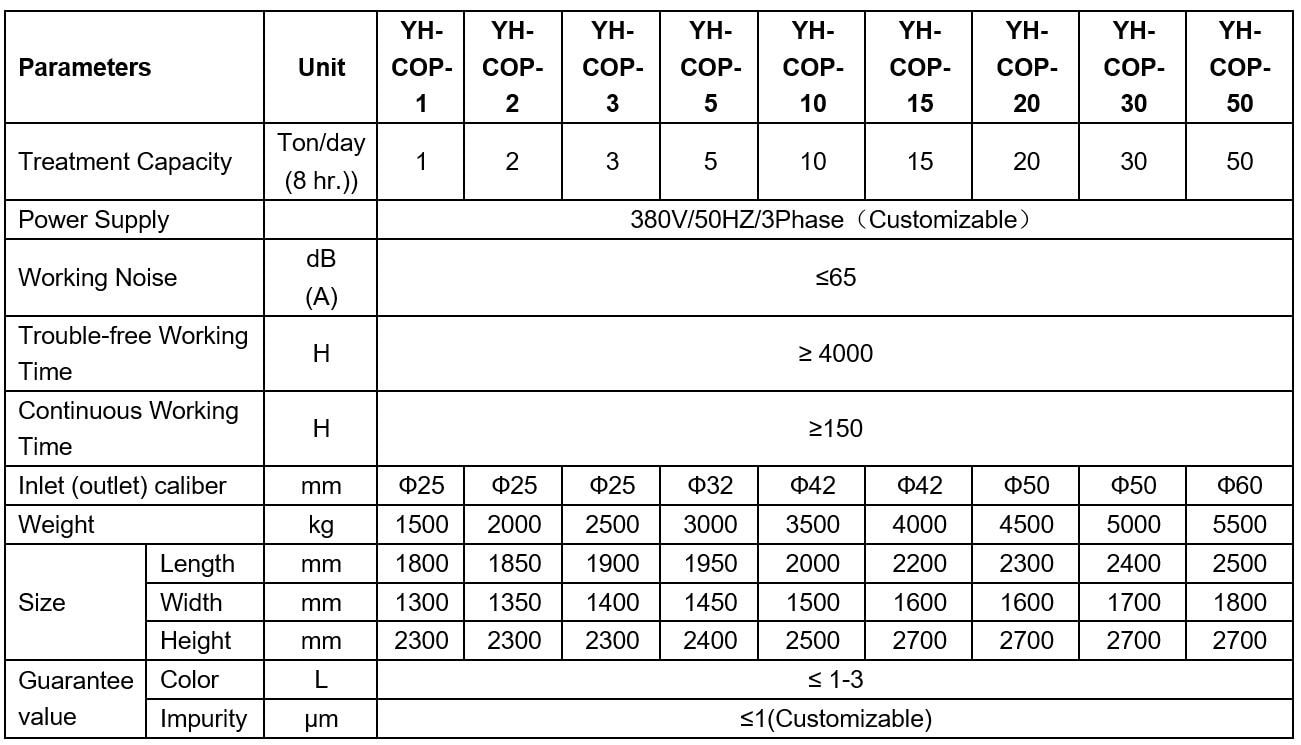

Technical Data:

Inquiry Now

series YH-ZYD-YELOCO

Series YH-TP791-YELOCO

series YH-ZYD-R-M-YELOCO

FREE ACCESS

FREE ACCESS