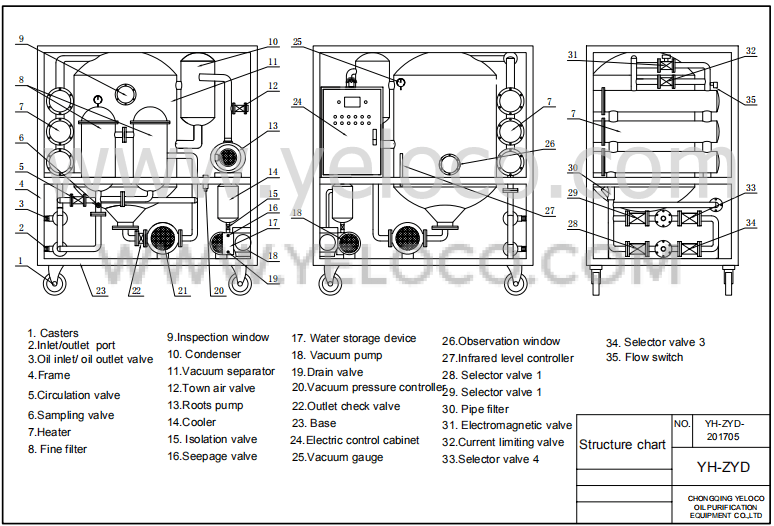

I. Why need YELOCO Double-stage Vacuum Transformer Oil Purification Machine?

The transformer is the “heart” of the power system, and transformer oil is the “blood” that keeps the heart beating. Excessive moisture, impurities, and acid value can cause insulation degradation, partial discharge, equipment aging, and even cause major accidents! Choosing an efficient and reliable oil purifier is to build a strong defense for power safety!

II. YELOCO Double-stage Vacuum Transformer Oil Purification Machine Advantages

**Accurate purification in one step**

• Original three-stage filtration system with an accuracy of 1.0 microns, which deeply removes moisture, particulate matter and free carbon;

• Vacuum flash evaporation + molecular adsorption technology eliminates dissolved gases and reduces the acid value by 95%;

• One-click detection of oil quality, exported oil meets new oil standards (GB/T 7595), dielectric strength ≥70kV!

**Intelligent and efficient, saving worry and effort**

• Fully automatic PLC control, touch screen operation + fault self-test, novices can get started quickly;

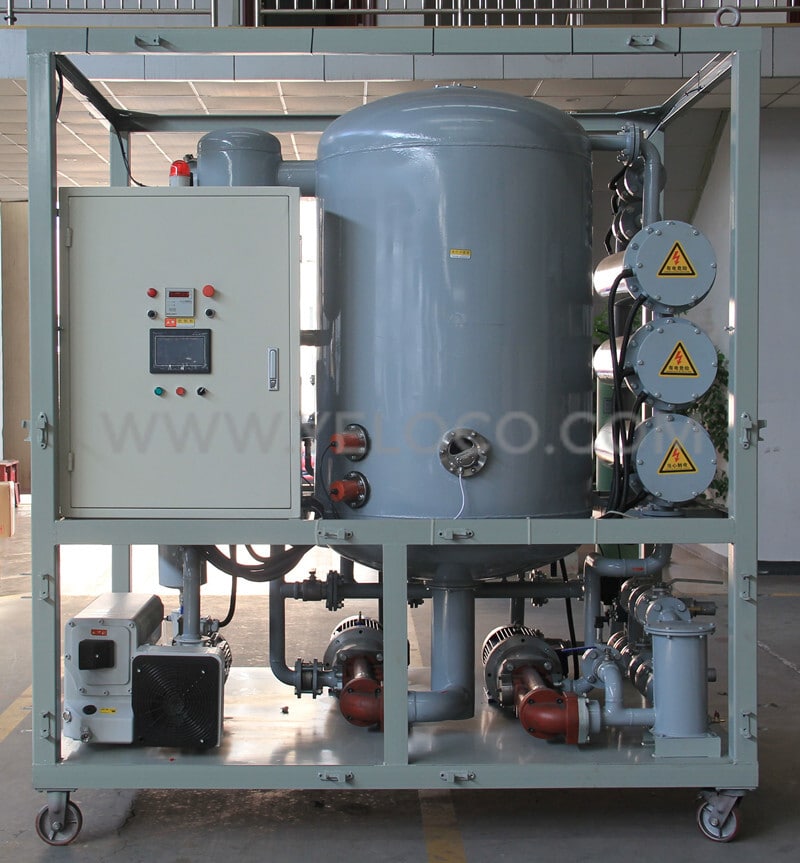

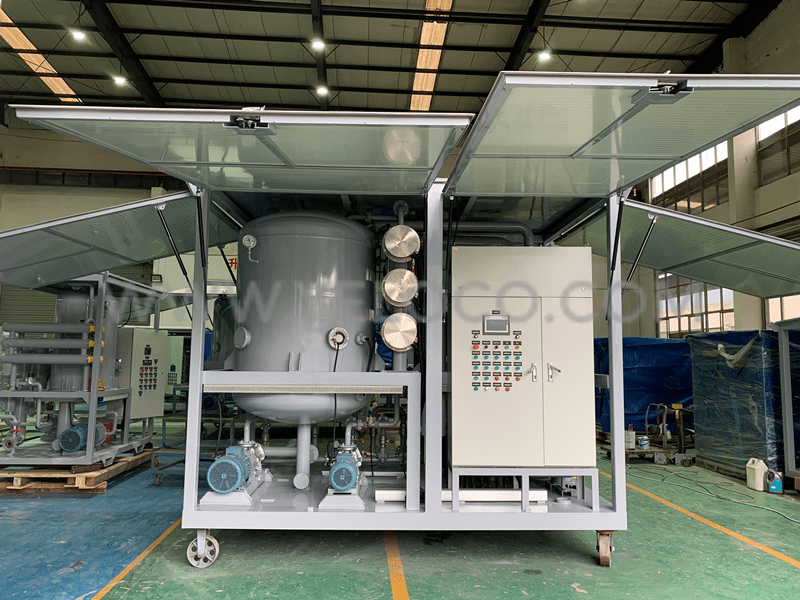

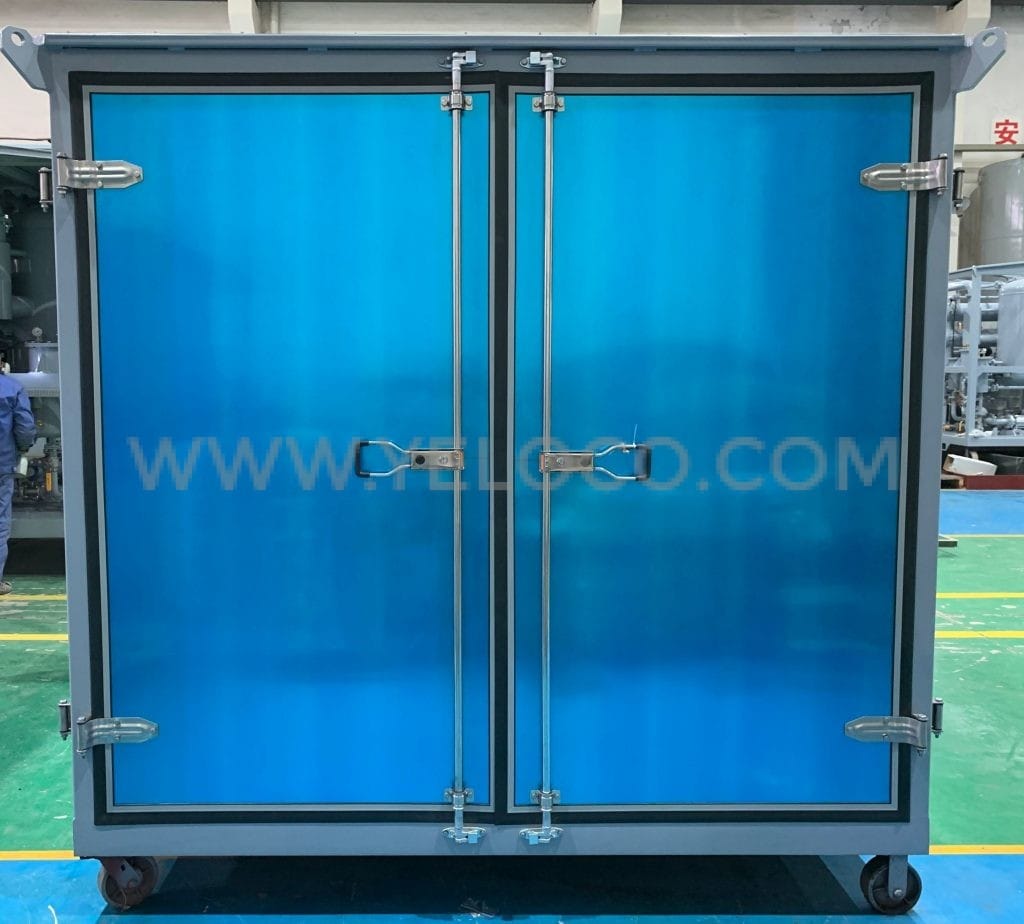

• Modular design, easy to move, and on-site deployment can be completed in 30 minutes;

• The processing capacity is 6000L/h, the energy consumption is reduced by 30%, and it can run continuously for 24 hours without any pressure!

**Safety first, durable and reliable**

• Explosion-proof structure + multiple safety interlocks to eliminate the risk of oil leakage and overheating;

• Aviation-grade stainless steel filter element, anti-corrosion life extended by 3 times;

• Suitable for extreme environments, stable operation in plateau, coastal and extremely cold areas!

**Green energy saving, cost reduction and efficiency improvement**

• Oil recovery rate exceeds 99%, saving over 1 million yuan in oil replacement costs annually;

• Zero wastewater and gas emissions, helping companies pass ISO 14001 certification;

• Extend the life of the transformer by 10 years, reduce downtime losses, and see a visible return on investment!

**Full service, lifelong escort**

• Free oil sample testing + customized purification plan;

• 24-hour engineer response, 10-year warranty for accessories;

• Witnessed by 100000+ customers around the world, long-term partner of State Grid and wind power giants!

**Full coverage of applicable scenarios**

✅ Purification before new oil injection ✅ Periodic maintenance of operating oil

✅ Rapid water and degassing for fault repair ✅ Regeneration of old transformer oil

III. MAIN TECHNICAL SPECIFICATIONS

|

Model: Series YH-ZYD-100 |

Flow rate: 6000L/h |

|

Oil flow capability: 100L/min |

Working pressure: ≤0.5MPa |

|

Limit vacuum: ≤5Pa |

Working vacuum: ≤80Pa |

|

Working oil temperature: 20~80℃ (Adjustable) |

Power: 60Hz 460V 3-phase and 4-wire |

|

Heating power: 67KW |

Overall power: 60KW |

|

Working noise: ≤80dB(A) |

Weight of the whole machine: 1850Kg |

|

Diameter of inlet and outlet pipes: 32/ 32mm |

Overall dimensions: 2150 ×1650× 2450mm |

|

Average trouble-free working time:≥5000h |

Lift: ≤20m |

IV. QUALITY INDICATORS OF TREATED OIL

|

Specification |

Unit |

YH-ZYD-100 |

|

Compression Value |

KV |

≥70 |

|

Volume of Water in Oil |

PPM |

≤5~8 |

|

Volume of Gas in Oil |

% |

≤0.1 |

|

Filtering Precision |

um |

1 |

V. How to operate the machine?

- Preparation Before Operation

* 1). Please read the instructions carefully before using the oil purifier machine and please operate according to the operation manual instructions.

* 2). Properly connect the inlet and the outlet of the oil pipe and testing pipe.

* 3). Ensure the inlet and outlet of the oil pipe are securely connected, the power supply input has the correct phase, acceptable and compatible power supply and electrical voltage, and the electrical control system is in the standby mode.

* 4). The equipment needs to adopt three-phase four-wire external power supply. The current carried by the external power supply line shall be greater than the total power indicated on the equipment nameplate. 3×35mm2+1×16mm2is recommended.

* 5). For using oil purifier machine, it must be reliably grounded. The cross-sectional area of the grounding cable shall not be less than the recommended wire diameter 25mm2.

* 6). It must be operated by specially trained personnel (the trainees must have knowledge of electrical system operation)

* 7). The operator is responsible for keeping the oil purifier working in correct conditions.

* 8). Before installing and using the oil purifier machine, checks shall be carried out according to the operating instructions. In particular, it must be checked to confirm whether the connecting positions of flange and fittings are correct and reliable, whether the cable terminals are firmly fastened, and whether the valve is properly opened/closed.

* 9). During transportation, only lifting and fork unloading are allowed (if forklift positions are provided by welding). During lifting, the lifting rope must be connected to the lifting lugs at the four corners of the equipment. For fork unloading, the forks shall be inserted into the special forklift holes of the chassis.

*10). The marks and symbols on the oil purifier machine shall not be changed or removed.

*11). It must be ensured that the vacuum pump will work at a temperature not lower than 12℃.

*12). The control system shall not be operated in the following places:

The places where the temperature or humidity is beyond the specified range.

The places where condensation occurs due to sharp changes in temperature.

The places with corrosive gas or inflammable and explosive gas.

*13). It is forbidden to operate the equipment when an alarm is given off from the equipment or parts are damaged. The equipment cannot be used again until the faults are removed and the damaged parts are repaired.

*14). Power-on check phase sequence: close the user’s power switch and close the product air switch; observe whether the “phase sequence error display lamp” is normal when it is not on. (When the light is on, it indicates a phase sequence error).

Correct the phase sequence (when the phase sequence is wrong): turn off the user power switch and replace any two-phase cable

2. Operation Procedures of Oil Purifier Equipment

(Two operation methods: Manual operation and Automatic operation)

Start operation of Transformer Oil Purification Machine (Manual method):

Turn the “manual/ automatic” knob switch to the “manual” position and press the “start” button switch.

2.1 Valve state for oil inlet and oil outlet interchange

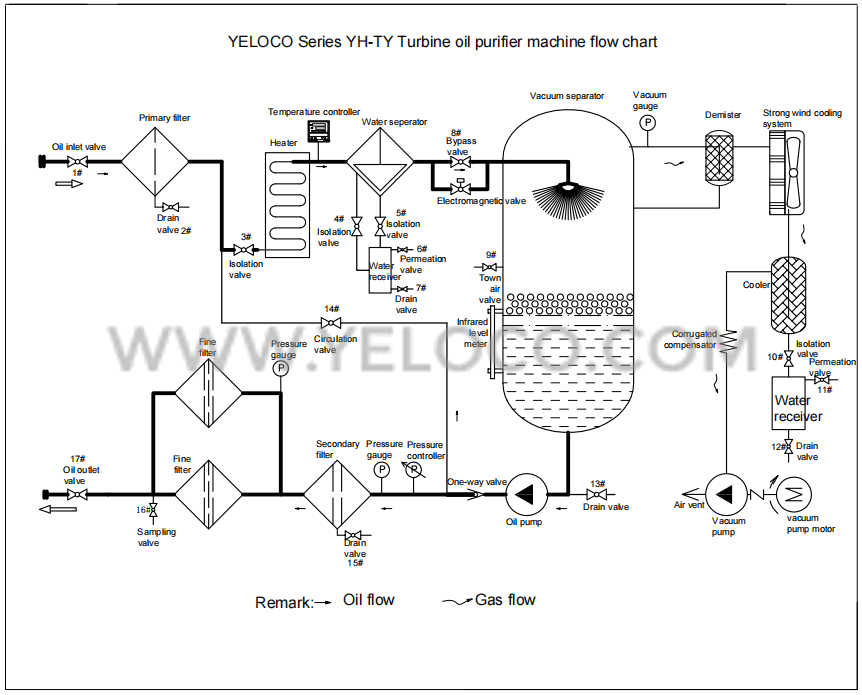

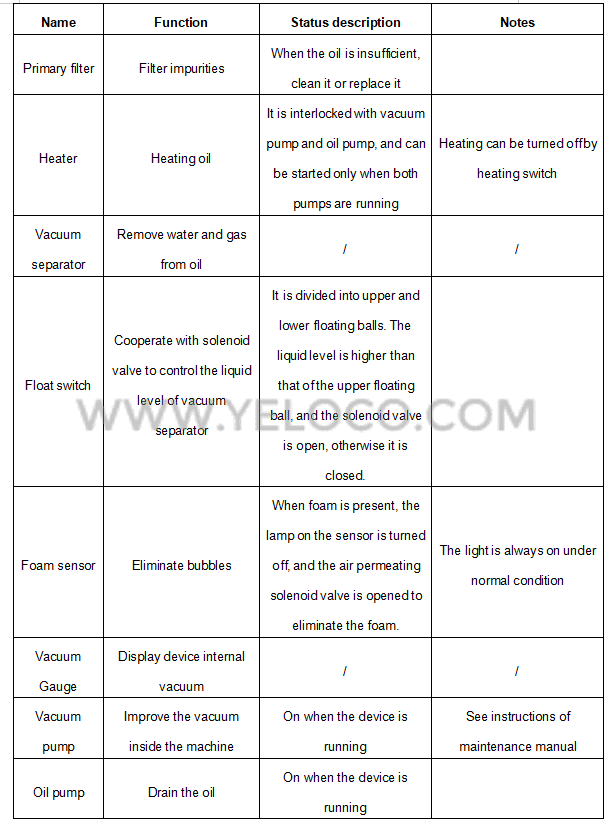

2.2 Start the vacuum pump

First check the liquid level of vacuum pump oil and the liquid level shall be between two scales (or in the middle of the observation glass); then press the “vacuum pump control” button, press the “vacuum pump control” button again, and press for three times repeatedly. Finally, observe the running state of the vacuum pump and the vacuum pump shall run smoothly. When the vacuum pump is in operation, the indicator light of the vacuum pump control button will be on.

2.3 Starting Roots pump

First check the liquid level of Roots pump oil and the liquid level in the oil cup. The liquid level is required to be between two scales (or in the middle of the observation mirror). Then when the vacuum gauge display value is less than 4500Pa, press the “Roots pump control” button, and then press the “Roots pump control” button again, and repeat the operation for three times. Finally, the operating characteristics of Roots pump are observed, which requires smooth operation of Roots pump. When the Roots pump works, the indicator light of the Roots pump control button will illuminate.

2.4 Open the inlet and outlet oil valve

When the vacuum gauge shows a value less than 100Pa, open valves and according to the oil pipe connection (set as A in and B out). Note: The operation method of the valve: Turn the handle clockwise to close and counterclockwise to open; when the handle position is parallel to the shaft, the channel is fully open; when the handle position is perpendicular to the axis, the channel is fully closed.

The operation of the valves below is the same. Operation of the valve is seen in the below figure.

2.5 Start the oil pump

When the oil level in the vacuum separation chamber rises to the middle of the observation mirror, press the “oil pump control” button, and then press the “oil pump control” button again, press for three times repeatedly to observe the operation characteristics of the oil pump and the oil pump shall work smoothly. When the oil pump is working, the indicator light of the oil pump control button will be on. Adjust “potentiometer” to change frequency of oil pump frequency converter and 40-50HZ is preferred.

2.6 Balancing the liquid level in vacuum separation chamber

Observe the liquid level in the vacuum separation chamber and adjust the frequency of the frequency converter of the oil pump. It is better that the oil inlet is slightly larger than the oil delivery.

2.7 Start the heater

Press heating 1 control button and then press heating 2 control button.

2.8 Adjust the temperature of the oil to be treated

Open the parameter setting screen of the text display and set the “heating temperature” to the desired value. The recommended temperature is 60℃.

2.9 Collect the oil sampling

After the temperature rises to 60℃, circulate and filter for 3-5 times, and collect oil samples from the sampling valve for inspection until the physical and chemical indexes of the filtered transformer oil are qualified.

3. Stop operation of Transformer oil purifier machine (Manual method):

Turn off the heater step by step (press the heating control button in turn) → close the oil inlet valve after 5 minutes → stop the roots pump → stop the vacuum pump 1→ stop the oil pump after the transformer oil in the vacuum separation chamber is drained out → close the oil outlet valve → cut off the product power switch → cut off the user power switch

4. Automatic operation of products:

4.1 Start operation of Transformer Oil Purification Machine (Automatic method) :

Open oil inlet valve and oil outlet valve first. Turn the “Manual/ Automatic” knob switch to the “Automatic” position and press the “Start” button switch. See the below figure for the Manual/ Automatic operation diagram:

Under the control of the programmable logic controller PLC, the product will orderly control various motors, heaters, AC contactor and other components.

(The machine automatically works process as follows:

Start the vacuum pump → Roots pump will start to work automatically when the vacuum degree is lower than the set value → Oil inlet solenoid valve will start to work automatically → Oil outlet pump will start work automatically after the liquid level reaches the low liquid level switch → Heater will start to work automatically (and perform constant temperature control) until the sampling is qualified before entering the next process. )

4.2 Stop operation of Transformer Oil Purification Machine (Automatic method):

In the automatic operation state, press the “Stop” button directly, and the equipment will stop working orderly under the control of programmable logic controller PLC.

(The process as below: Stop heating → Delay for 5 minutes (adjustable) → Stop oil inlet solenoid valve → Stop Roots pump→ Stop vacuum pump→ Stop oil outlet pump when low level switch detects that the liquid level is “None”.)

5. Product emergency stop operation:

Press the emergency stop button to disconnect the main power air switch.

VI. REPAIR AND MAINTENANCE

1. Maintenance of the whole unit

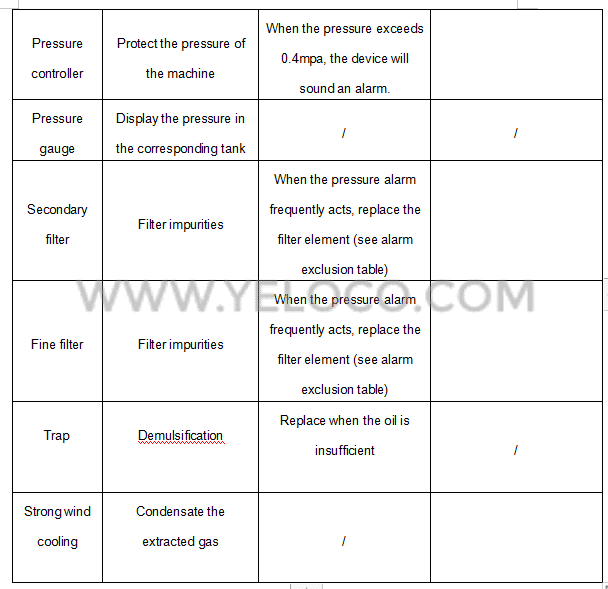

|

Period |

Operations |

|

Daily |

Check whether the electrical connection is subject for overheating |

|

Daily |

Check whether there is spark at the static and dynamic points of the contactor. |

|

Monthly |

Check whether the action of the solenoid valve is reliable. According to whether the sound is abnormal when starting and stopping, it is determined whether there are impurities in the iron core and armature matching. Check the iron core for wear. Is the seal aging |

|

Every three month |

Check whether the connection terminals are loose |

|

Every three month |

Check whether the connecting bolts are loose or not. |

2. Maintenance of vacuum pump (see original instructions of vacuum pump for details)

|

Period |

Operations |

|

Daily |

Check oil level |

|

Daily |

Check state of gas discharging (no black smoke) |

|

Daily |

Check whether the pump down time is normal |

|

Equipment downtime is over 120H |

Before shutdown, close the oil inlet and outlet valves of the product; operate the vacuum pump over 1.5H |

|

Every half year / operating for 1200h |

Replace the original oil of vacuum pump, model is “VM100” and replace oil filter element (if any) |

|

Every year / operating for 2400h |

Replace gas discharging filter element |

3. Maintenance Roots pump (see original instructions of Roots pump for details)

|

Period |

Operations |

|

Daily |

Check oil level |

|

Daily |

Check whether there is lubricating oil in the oil cup at the shaft seal end. |

|

Every year / operating for 2400h |

Replace oil of Roots pump, model is “Anderol 555” |

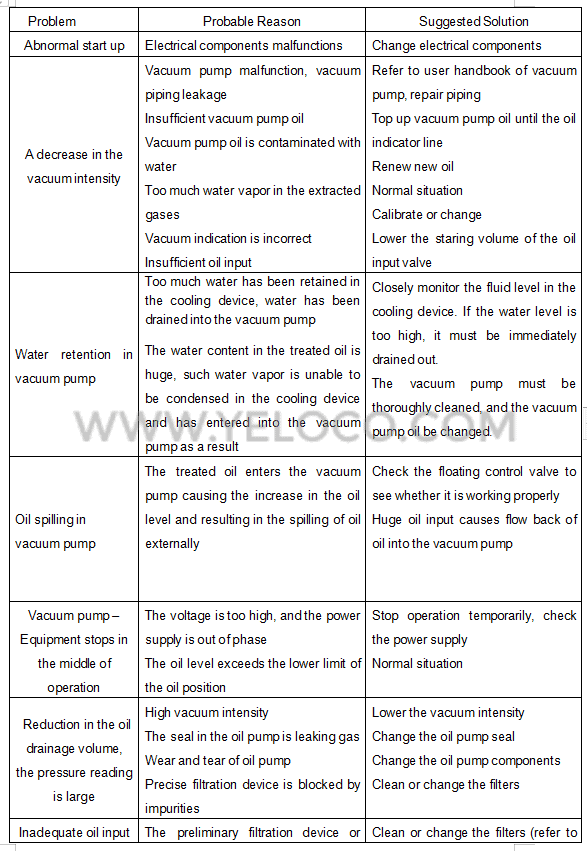

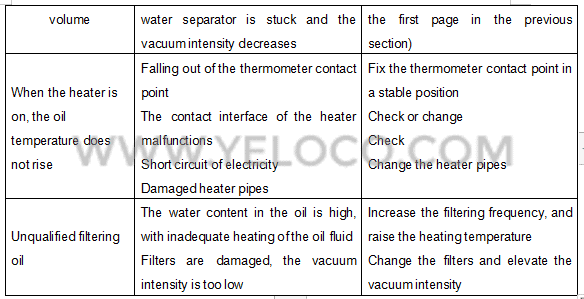

VII. Faults of products and repair

1. The oil inlet volume is small and the liquid level balance for normal operation of oil purifier can’t be sustained:

|

Reasons for faults |

Repair method |

|

Oil inlet valve is damaged |

Replace oil inlet valve |

|

The coarse filter element is blocked |

Clean or replace the coarse filter element |

|

Solenoid valve is damaged |

Replace solenoid valve |

|

Gas leakage between oil tank and oil inlet |

Check and repair |

2. The product is subject to shutdown with alarm

2.1 Shutdown for excessively high liquid level

| Reasons for faults | Repair method |

| Solenoid valve element is blocked | Check and restore the valve element |

| The water content in the oil is too high, and a large amount of foam appears in the vacuum separation chamber . | Reduce vacuum degree a little, after large quantity of water content is removed, then restore high vacuum degree |

| Low liquid level switch fails | Replace liquid level switch |

| Leakage between oil tank and oil inlet | Check and repair |

| After the fault is repaired, the machine can’t work normally again until the oil fluid in is drained out exhausted . | |

2.2 Shutdown for over-pressure

| Reasons for faults | Repair method |

| Fine filter element is blocked | Check and restore the valve element |

| Outlet oil valve is closed for error operation | Check and open the oil valve |

| Outlet oil valve is damaged | Replace the oil outlet valve |

3. The noise of oil pump rises suddenly

| Reasons for faults | Repair method |

| The oil liquid level in the vacuum separation chamber is too low | Repair based on fault 1 |

| The vacuum separation chamber is full of foam | Reduce vacuum degree a little, after large quantity of water content is removed, then restore high vacuum degree |

4. The equipment shuts down suddenly

When the equipment stops suddenly due to power failure during operation, it is necessary to close the oil inlet and outlet of the equipment to prevent oil being sucked back into the vacuum separation tank and then into the vacuum pump and the vacuum pump oil will be contaminated.