- Categories

- Double-stage vacuum Transformer oil filtration machine

- Double-stage vacuum Transformer oil regeneration machine

- Single-stage vacuum Transformer oil purification machine

- Ultra-high voltage Transformer oil purifier machine for more than 350KV Transformer

- Transformer oil vacuum system

- Turbine oil purifier machine

- Lube oil filter / Hydraulic oil filter

- Online On-Load Tap Changer oil purifier

- Cooking oil purifier machine

- Waste Engine Oil Distillation machine

- High viscosity gear box oil purifier machine

- Refrigeration oil purifier machine

- Phosphate Fire-Resistant oil purifier

- Fuel oil purifier

- Portable oil purifier machine

- Oil Filling Machine

- Oil tester

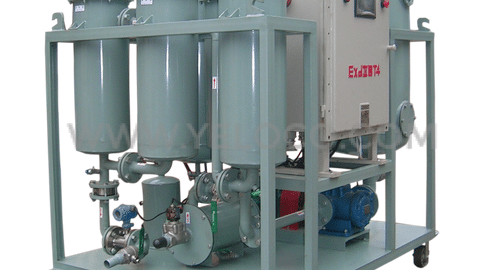

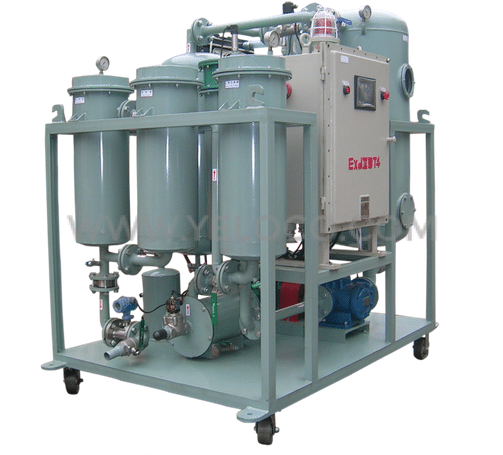

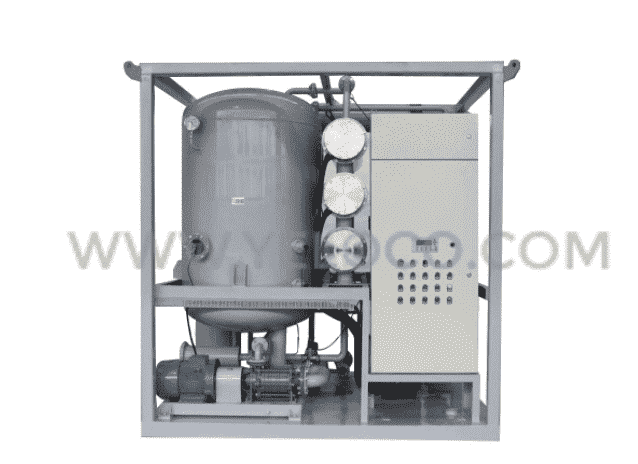

Anti-explosion turbine oil purifier

series YH-TY-A–YELOCO

Why does an oil purifier machine need anti-explosion?

The explosion-proof vacuum oil purifier machine is mainly designed for the petroleum, petrochemical, chemical, coal, metallurgy, power plant, and other inflammable and explosive gas environments.

The explosion-proof oil purifier machine mainly refers to the explosion-proof electrical components and motors. Generally, when an electric spark is produced due to the contractor or poor contact wire, this machine adopts comprehensive anti-explosion measures.

Application:

The anti-explosion turbine oil purifier machine is used for treating the unqualified turbine oil and especially the seriously emulsified turbine oil. It can effectively remove oil moisture, impurities, gas, and volatile compounds such as ammonia and other harmful ingredients from oil, and improve the oil quality and recovery using the properties of the oil.Advantages:

- Intuitive design, small size, lightweight, flexible movement, simple and convenient operation, highly automated, safe control, advanced yet reasonably priced.

- Equipped with a unique and advanced medium cooling system.

- Breaks emulsification thoroughly through polymeric material filters.

- Has a complete oil level automatic compensation controller to solve oil pump no-load and running oil phenomenon.

- Pressure protective system to ensure machine operates easily and safely.

- Interlocked protective system that connects oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leakage and electricity leakage. If there is any fault, the machine will turn off automatically. Operation is very safe.

- Designed for the use of flammable and explosive environment.

- The vacuum oil filter, electric heater, electric control cabinet, pressure controller, and cable can be used for special explosion-proof products.

- Precision multi-stage filtration system, which effectively removes the impurities in the oil.

- Super dehydration and degassing system removes water, gas, and light hydrocarbon in oil efficiently and quickly.

- Advanced automatic constant temperature control system, automatic liquid level control system, automatic pressure protection system, and excellent configuration to ensure high performance of the equipment operation.

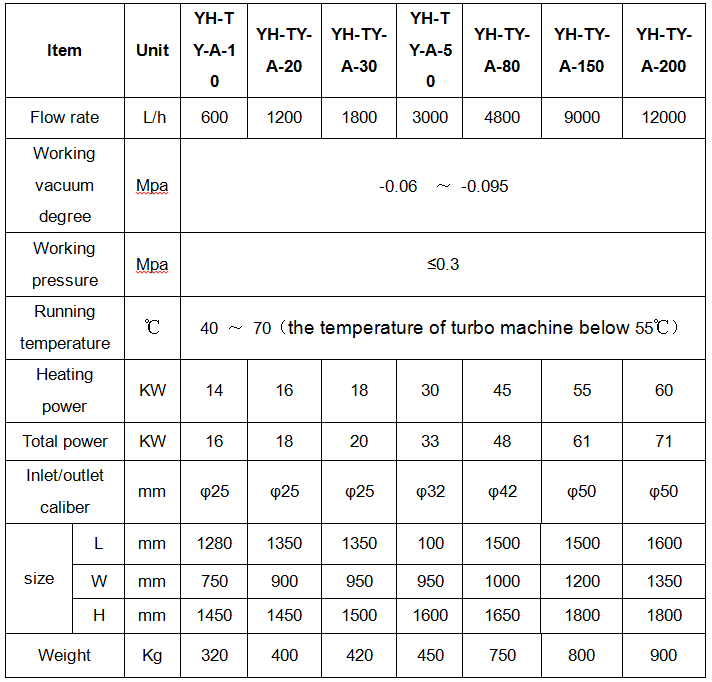

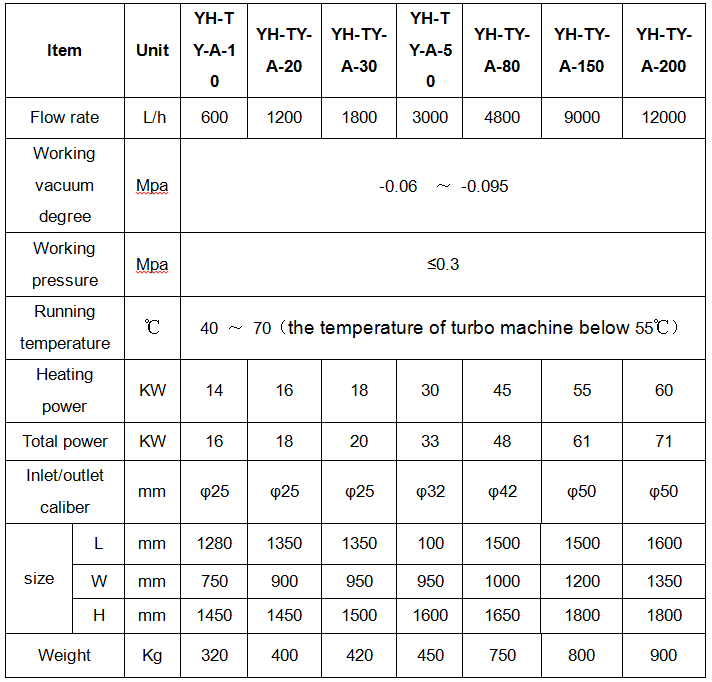

Technical Data

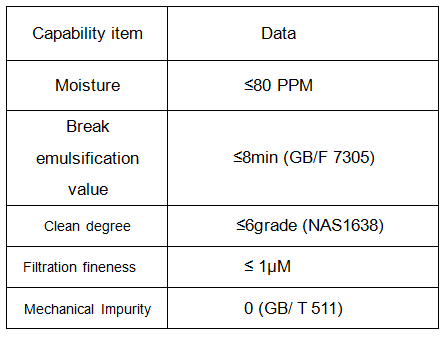

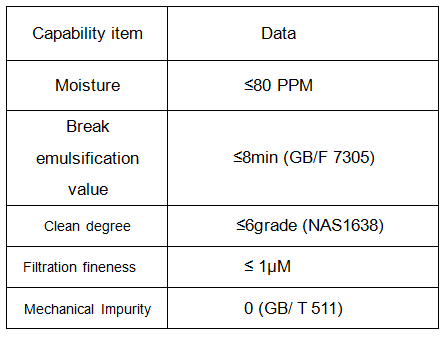

Oil Data After Purification

Inquiry Now

More Products

series YH-TY-A–YELOCO

Anti-explosion turbine oil purifier

Series YH-OLTC-YELOCO

Online On-Load Tap Changer Oil Purifier

series YH-ZYD-YELOCO

Double-stage vacuum transformer oil filtration machine

Series YH-TYR-YELOCO

Refrigeration oil purifier machine

FREE ACCESS

FREE ACCESS